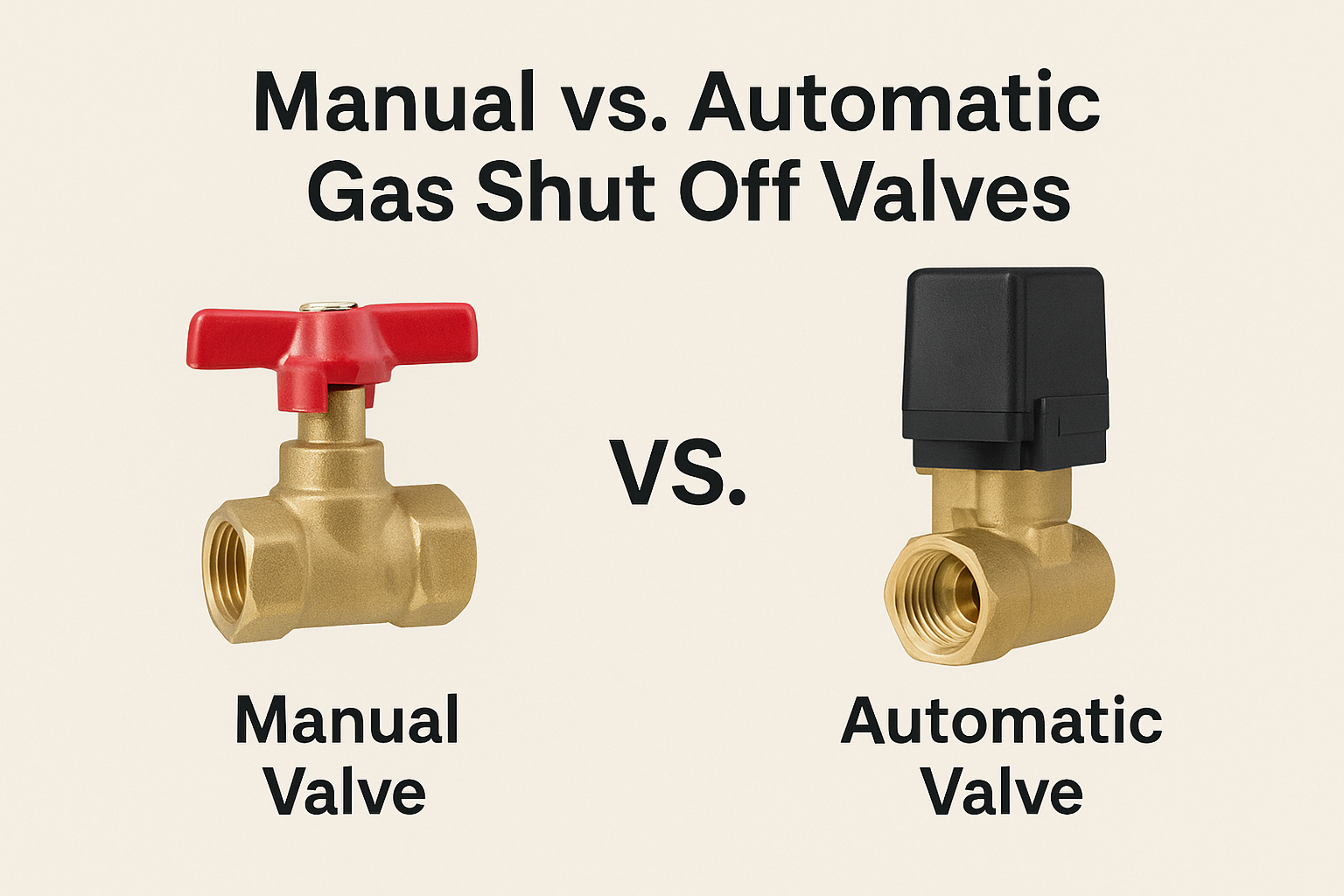

Gas shut off valves are essential for controlling gas flow and preventing accidents in homes, businesses, and industrial setups. Whether it’s a gas line shut off valve for routine maintenance or an automatic gas shut off valve for emergencies, choosing the right type is crucial. This guide compares manual and automatic options, including earthquake gas […]

Actuator valves are essential components in industrial, commercial, & residential systems, enabling precise control of fluid and gas flow. Among them, electric actuator valves are widely used due to their automation, accuracy, & safety. Understanding the electric actuator valve working principle helps operators select the right solution for their application. Whether you’re sourcing from a […]

In any plumbing or industrial water system, check valves for water play a crucial role in maintaining safe, reliable, & one-directional flow. Whether it’s a residential hot water line or a large industrial pipeline, a check valve ensures the fluid moves forward and blocks any reverse flow that could damage equipment or contaminate clean water […]

Knowing whether a valve is open or closed is essential for safe operations in industrial systems. Whether you’re working in oil & gas, chemical processing, water treatment, manufacturing etc, correctly identifying valve position helps prevent accidents, leaks & equipment failure. In this guide, we’ll walk you through how to confirm the position of the most common industrial […]

Every industrial system must have valves to control the flow of liquids and gases. In oil refineries and water treatment plants, the efficiency and safety of the system depend on picking the right type of valve. Ball valves, gate valves, and globe valves are some of the most common, and each has different internal designs […]

In each business gadget, valves play a essential role in making sure clean, safe, and efficient operation. But now not all valves are created equal. The difference often comes right down to how they’re designed, tested, and certified. This is in which diagnosed international industrial valve standards like API 6D and API 600 come into […]

In every industrial and mechanical system, valves are important parts that control the flow of liquids and gases in a system under various conditions. Even the most robust valves develop problems with time, which become inefficient and create leaks that result in costly system downtimes. Hence, learning how to recognize and solve some of the […]

Each system in an industrial location, there is an oil refinery, power plant or chemical function, uses valves to maintain flow, regulate pressure and secure safey during operation. Surprisingly, one of the biggest problems with faults comes from the equipment lack of proper maintenance on the valve. If the valve is not inspected, served or […]

Chemical plant life handle competitive acids, caustics, and hazardous media daily. Using wellknown steel valves in such environments can cause fast put on, leaks, and perilous disasters. This is where PFA lined ball valves and corrosion resistant valves are available in, offering unmatched protection and sturdiness in critical operations. The Role of PFA Lined Valves […]

The use of highly agrosive and corrosive chemicals under high pressure has made maintaining safety, reliability and efficiency in industrial plants very challenging. Even the smallest of valve malfunctions can lead to, safety and economic disasters such as unplanned downtimes and huge catastrophic events. In this case, we review how outstanding the operational safety, maintenance […]